Revisiting Lean Process Design: A Needed Refresh

Last week, I attended a training session on lean process design led by Murat Özbilen. As an industrial engineer, most of what we discussed wasn’t new to me. Still, revisiting the fundamentals sometimes proves to be the best way to refine your approach.

This training served as a reminder: even when you know the tools and frameworks, the real challenge is applying them intentionally, especially when daily work tends to bury the basics under urgency and habits.

What is a Process, Really?

A simple definition I’ve known since my earliest lectures:

Input → Steps → Output → Ecosystem.

No matter the industry. Whether it’s a production line or software development, the pattern holds true. Processes show up in three broad types:

- Operational processes: the core work (order management, supply, delivery).

- Support processes: the backbone (HR, finance, admin).

- Management processes: steering the ship (budgeting, planning, strategy).

It’s so basic that it’s easy to skip over, but when you do, you forget where waste hides.

Why Improve What Works?

Process improvement serves to motivate, enhance efficiency, improve quality, and reduce costs. In reality, though, improvement is rarely about tweaking steps; it’s about questioning assumptions.

Sometimes you need a “cookie game” (yes, we played one) to expose invisible inefficiencies. Sometimes you need an external eye to remind you to ask: Is this step really necessary?

Common Pitfalls

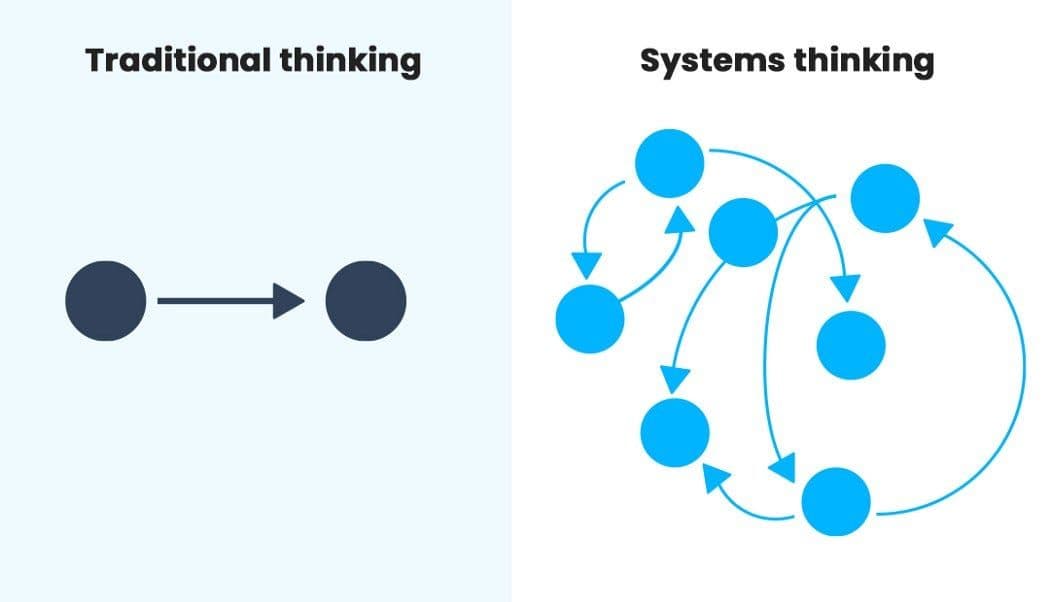

Most unsuccessful improvements share the same root cause: rushing to solutions without fully understanding the problem.

It’s easy to fall into mechanical thinking, breaking things into tasks and controlling each part, without stepping back to see if you’re even addressing the right issue.

The training emphasized the importance of strategic thinking, focusing on the core and questioning how things are connected. An example shared was studying how an F1 pit crew operates to redesign an ambulance process. Unexpected perspectives often reveal the best solutions.

Lean Process Design: The Essentials

Here are some notes I’m keeping top of mind:

1. Define the Problem Clearly

Profit, for example, breaks down to “Profit = (Price – Cost) x Volume”. So where’s your leverage? New markets? Positioning? Cost structure?

2. Build the Right Team

The fundamentals still matter: assemble knowledgeable people, keep everyone engaged, appoint a champion, and ensure decision-makers are accessible.

3. Balance Quick Fixes and Long-Term Fixes

Sometimes a costly quick action can buy time, but it must be verified and only temporary.

4. Use the Right Tools for Root Causes

- SIPOC

- Fishbone (Ishikawa)

- Pareto

- 5 Whys

- Value Stream Mapping

- Theory of Constraints: focus on the bottleneck (The Goal and Critical Chain by Eli Goldratt are still classics).

5. The Loop Never Ends

PDCA: Plan, Do, Check, Act. Keep cycling through.

Timeless Tools

Every method was a page straight out of my industrial engineering textbooks, but seeing them all together again reminded me how often they are overlooked in practice.

- Kaizen, Lean, TQM, Six Sigma: define, measure, analyze, improve, control.

- 5S: Sort, Set in Order, Shine, Standardize, Sustain.

- ECRS: Eliminate, Combine, Rearrange, Simplify.

- SCAMPER, Poka Yoke: Design the work to prevent errors. For example use physical barriers, sensors, visual cues, and checklists.

- Always watch for Muda: waste from overproduction, waiting, excess transport, and unnecessary processing.

This wasn’t a new toolkit for me. Yet, it was a valuable pause to check if I’m really using what I know. Theory fades fast when you’re deep in daily operations. Whether I’m designing a mentoring program, running a project, or fixing a broken process, the same question applies: Are we asking the right questions and looking at the root, or just tweaking the surface? Sometimes, the basics are the real competitive edge.